Introduction to Bird Bath Optical Module

In the world of optical engineering, few designs have revolutionized compact imaging systems as dramatically as the bird bath optical module. This ingenious configuration, named for its resemblance to the classic bird bath shape, represents a paradigm shift in how engineers approach space-constrained optical applications.

At ARVROptical.com, we’ve witnessed firsthand how this technology has enabled breakthroughs across industries – from military targeting systems to smartphone cameras. This comprehensive guide will explore:

- The physics behind bird bath optical designs

- Detailed component breakdowns and configurations

- Current applications transforming multiple industries

- Technical advantages over traditional optical layouts

- Emerging innovations pushing the boundaries of folded optics

- Selection criteria for implementing these systems

Chapter 1: The Physics of Folded Optics

1.1 Basic Operating Principle

Bird bath optics utilize a clever arrangement of mirrors to fold the optical path while maintaining image quality. The fundamental design consists of:

- Primary Mirror: Typically a concave spherical or parabolic surface

- Secondary Mirror: Flat or slightly curved mirror positioned at 45°

- Corrective Optics: Lenses or additional mirrors that compensate for aberrations

This configuration allows light to make a 90° turn while significantly reducing the overall system length compared to straight-path designs.

1.2 Historical Development

The concept originated in World War II periscope designs, where engineers needed to:

- Maximize optical path length in confined submarine spaces

- Maintain image clarity through multiple reflections

- Withstand harsh environmental conditions

Modern iterations have evolved through:

- 1960s: Space telescope applications

- 1980s: Medical imaging adaptations

- 2000s: Consumer electronics miniaturization

1.3 Key Optical Parameters

Critical performance metrics include:

- Focal Length: Typically 25mm-200mm in compact systems

- f-number: Usually between f/2.0 to f/4.0

- Field of View: Ranging from 5° to 40° depending on application

- Wavefront Error: < λ/4 RMS for high-performance systems

Chapter 2: Component-Level Breakdown

2.1 Mirror Designs

Primary Mirror

- Material: Typically aluminum or glass substrates

- Coating: Protected silver or enhanced aluminum

- Surface Accuracy: λ/10 or better for imaging systems

- Mounting: Often kinematic mounts for precise alignment

Secondary Mirror

- Tilt Accuracy: < 0.1° critical for performance

- Size: Typically 30-50% of primary diameter

- Coating Options: Dielectric for specific wavelength ranges

2.2 Corrective Optics

Modern systems often incorporate:

- Aspheric lenses to reduce spherical aberration

- Field flatteners for improved edge performance

- Achromatic doublets for color correction

2.3 Mechanical Considerations

- Material Selection: Aluminum alloys for weight, invar for thermal stability

- Alignment Mechanisms: Precision micrometers or piezo actuators

- Environmental Sealing: IP67 or better for harsh environments

Chapter 3: Industry Applications

3.1 Defense & Aerospace

- Gunner Sights: M1 Abrams tanks use variants for compact targeting

- Drone EO/IR Systems: Enables high-performance optics in UAVs

- Missile Seekers: Miniaturized infrared detection

3.2 Medical Technology

- Endoscopes: 3mm diameter systems for minimally invasive surgery

- Ophthalmic Devices: Retinal imaging systems

- Dental Cameras: Intraoral imaging probes

3.3 Consumer Electronics

- Smartphone Cameras: Periscope zoom modules

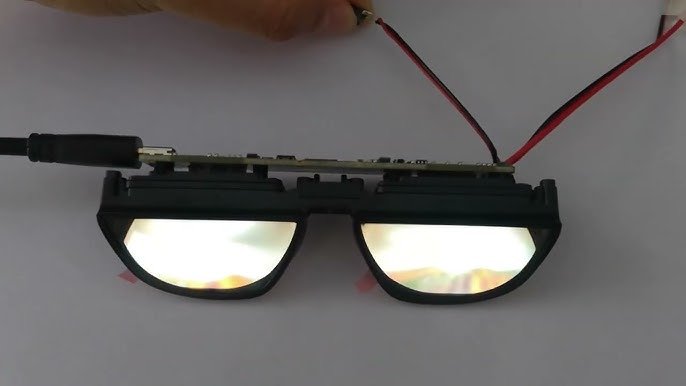

- AR/VR Headsets: Compact display projection

- Action Cameras: High-zoom capabilities in small form factors

3.4 Scientific Instruments

- Compact Spectrometers: Field-deployable units

- LIDAR Systems: Automotive and topographic scanning

- CubeSat Telescopes: Space-constrained astronomy

Chapter 4: Technical Advantages

4.1 Size and Weight Benefits

| Parameter | Reduction vs. Linear Systems |

|---|---|

| Length | 60-80% shorter |

| Volume | 50-70% smaller |

| Weight | 40-60% lighter |

4.2 Performance Characteristics

- Improved Stray Light Control: Built-in baffling

- Reduced Sensitivity to Vibration: Compact form factor

- Better Thermal Stability: Shorter air paths

4.3 Cost Considerations

While initial development costs are higher, bird bath optical module offer:

- Reduced material costs: Fewer optical elements

- Lower assembly time: Pre-aligned modules

- Decreased shipping costs: Smaller packaging

Chapter 5: Emerging Innovations

5.1 Freeform Optics

Next-generation systems are incorporating:

- Non-symmetric mirror surfaces for aberration correction

- 3D-printed optical elements with complex geometries

- Graded-index materials for improved performance

5.2 Active Alignment Systems

- MEMS-based mirror control for dynamic focusing

- Machine vision-assisted assembly for precision alignment

- Real-time wavefront sensing for adaptive optics

5.3 Hybrid Designs

Combining bird bath optical module principles with:

- Diffractive optical elements

- Metasurface technology

- Liquid crystal optics

Chapter 6: Implementation Guide

6.1 Selection Criteria

When specifying a bird bath module, consider:

- Spectral Range: UV, VIS, or IR performance

- Environmental Requirements: Temperature, humidity, shock

- Interface Needs: C-mount, F-mount, or custom

- Regulatory Compliance: MIL-STD, ISO, or medical certifications

6.2 Integration Tips

- Thermal Management: Allow for coefficient of expansion

- Vibration Isolation: Use damping mounts in harsh environments

- Alignment Verification: Laser collimators or interferometers

6.3 Maintenance Best Practices

- Cleaning Procedures: Proper handling of coated surfaces

- Storage Conditions: Controlled humidity environments

- Re-alignment Protocols: Factory recommended procedures

Why Choose ARVROptical for Bird Bath Optical Modules?

At ARVROptical.com, we offer:

Custom optical design services

Precision manufacturing capabilities

Complete testing and characterization

Rapid prototyping options

Our team has delivered bird bath optical module solutions for:

- Military targeting systems

- Medical imaging devices

- Space-constrained scientific instruments

Contact our optical engineers today to discuss your project requirements!

The Future of Folded Optics

As miniaturization demands grow across industries, bird bath optical modules will continue evolving through:

- Nanostructured surfaces for enhanced performance

- AI-optimized designs for specific applications

- Mass production techniques for consumer markets

Ready to leverage this transformative technology?

Explore our optical solutions or speak with our technical team about your specific needs.